Good insulation reduces your energy bill and increases thermal comfort, but it lowers the natural ventilation of your house. Luckily, there are several good ventilation options that prevent heat loss or gain.

Heat-recovery ventilation options include a rotary wheel, a fixed plate system, a heat pipe, or a run-around system. When your ventilation drops below 0.35 air changes per hour you will need to improve your ventilation.

Continuous ventilation is important to maintain good indoor air quality, which is important for our health and wellbeing. Additionally, proper ventilation prevents condensation and mold.

At the end of this post, you will find an overview table with the efficiencies, advantages, and disadvantages of four heat-recovery ventilation options.

When should I increase ventilation?

Natural infiltration of outdoor air, even in a well-insulated house, is a large contributor to ventilation. However, when the air exchange rate of your house falls below a certain amount, an increase in ventilation is highly recommended. This amount, according to the American Society of Heating, is about 0.35 air changes per hour (ACH) for the living room. (source)

The air exchange rate (ACH) is the volume of air that is exchanged with fresh outdoor air per hour. It can be calculated by taking the number of cubic feet (approximately 28 liters) of air that is refreshed every hour and dividing that by the volume of the building.

To be able to measure this, you need to know the airflow in your house. You might have to contact an expert with the right equipment to measure this for you. Otherwise, you can find more information on Wikihow.com.

So, you measured or suspect that you have a low air exchange rate and want to increase your ventilation. There are several options available.

Ventilation without losing or gaining heat

When you properly insulate your house, most of the natural ventilation of walls, doors, and windows is lost. Of course, this was part of the goal of insulating. However, continuous ventilation of the indoor air is necessary for good indoor air quality. Therefore, ventilation options that do not cause heat loss or gain, depending on your local climate, are a necessity.

There are several ventilation options you can go for.

- Passive ventilation

- Active ventilation

- Mixed-mode ventilation

Passive ventilation

Passive ventilation occurs naturally through a difference in pressure between outdoor and indoor air. This pressure difference is either caused by the wind or by a temperature difference between the indoor and outdoor air.

Passive ventilation mainly occurs through:

- ventilation grilles

- chimney

- building design for ventilation (e.g. Orientation of the ridge toward common wind direction)

- cracks and leaks (in a poorly insulated house)

A well-insulated house that is not designed with ventilation in mind can lack sufficient ventilation, as a great deal of its natural ventilation is lost.

So, if your house is recently insulated to improve energy efficiency and thermal comfort, you should consider installing active ventilation.

Active ventilation

An active ventilation system actively controls the ventilation of your house through energy-operated fans. It makes sure your indoor air is always fresh. You likely already have some form of active ventilation like an extractor fan in your kitchen and bathroom. These are installed because the kitchen and bathroom frequently require ventilation due to excessive moisture. Since extractor fans normally only remove moist air, it is advised to have an air vent in the same room to replace the extracted air.

Mixed-mode ventilation

A mixed-mode ventilation system is a combination of natural en mechanical ventilation, mostly used in offices. It is a highly technical system that measures indoor temperature, CO2 levels, and humidity. When natural ventilation is insufficient, a mixed-mode system switches on to maintain preferred air quality as well as cooling or heating.

This system can range from an air conditioner that shuts down when a window is opened to a system that controls active ventilation and automatic windows.

Mechanical ventilation with heat recovery

A heat recovery ventilation system allows for air exchange between the indoor and outdoor air without heat loss or gain. This is accomplished by heat exchange between both airflows running alongside each other. Hereby, the incoming air picks up most of the heat from the outgoing air. In case you need cooling, it also works the other way around.

A heat recovery ventilation system can prevent about 60 to 95% of heat loss (or gain). (source)

There are four types of heat-recovery systems:

- rotary wheel

- fixed-plate

- heat pipe

- run-around

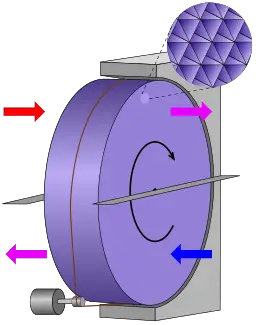

Rotary wheel

A rotary wheel is a low speed rotating porous wheel that is driven by electricity. Outgoing and incoming air simultaneously flow through the wheel and exchange heat with an efficiency of about 80%. This high energy recovery efficiency results in a short payback time of less than one year.

A disadvantage of a rotary wheel is that cross-contamination can take place between both airflows. So, unwanted moisture or air pollutants can be exchanged as well and be brought back into the house.

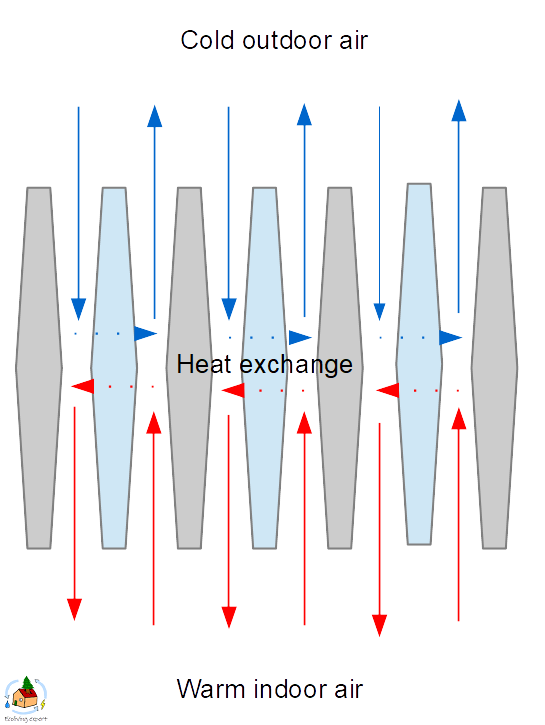

Fixed plate ( or recuperator)

A fixed plate heat-recovery ventilation system consists of several thin plates stacked together to create channels for air to flow through. Within a fixed plate system two different air flows run along each other exchanging heat through the thin plates.

Depending on the orientation of the fixed plate, the airflow patterns, and the type of material, a heat recovery of up to 93% can be achieved. (source) A disadvantage of a fixed plate is that their efficiency depends on many factors that are not always easily controlled. Additionally, there is the possibility of moisture buildup inside the fixed plate system.

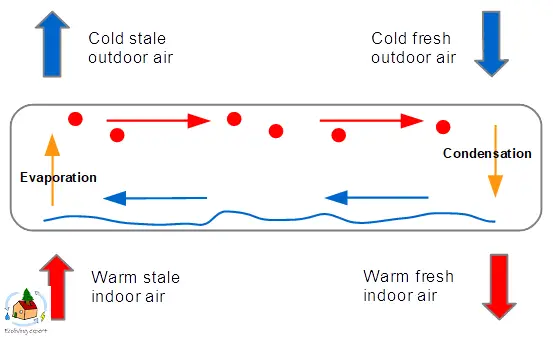

Heat pipe

Heat pipes use a liquid in a closed pipe to exchange heat between outgoing and incoming air. Hereby, outgoing hot air flowing along the pipe transfers its heat to the liquid, making the liquid evaporate. The incoming cool air flows along the evaporated liquid, taking up the heat and causing condensation.

The efficiency of heat pipes is about 50% but is increasing due to continuous testing and improving on the technology. Heat pipes stand out due to their handy manufacturing and convenient maintenance. Additionally, heat pipes prevent any form of contamination as it is a closed system.

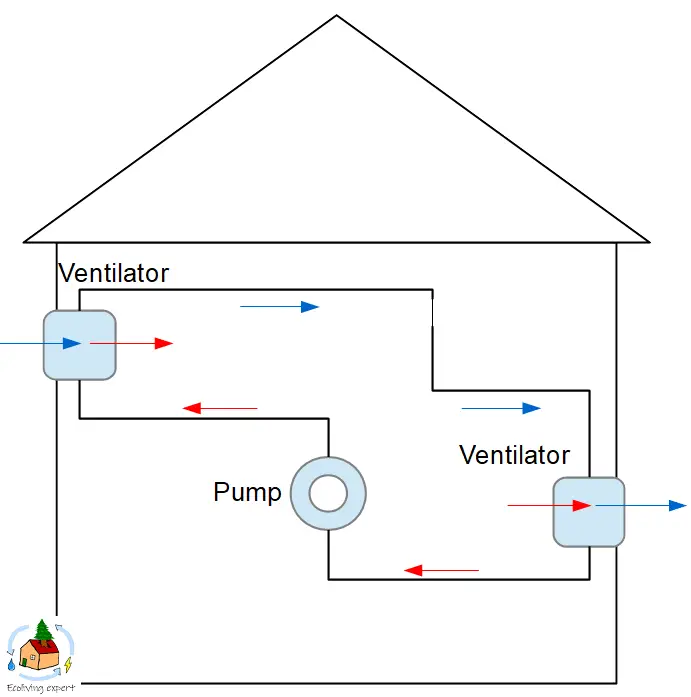

Run-around system

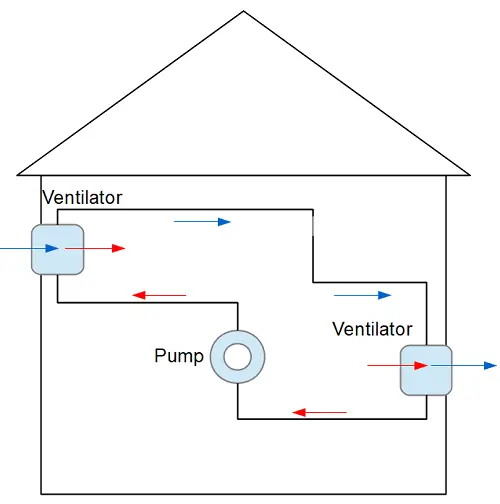

A run-around system is similar to a heat pipe but consists of two separate ventilators in different locations. The outgoing warm indoor air evaporates the liquid in the piping when vented out. A pump transfers the evaporated liquid from one ventilator to the other through the piping. The heat from the liquid is then transferred to the incoming cold outdoor air.

The main purpose of a run-around system is to avoid cross-contamination by not letting the incoming and outgoing air come in contact with eachother during the heat exchange.

The heat-recovery efficiency of a run-around system is about 45-65%. Additionally, a run-around system can increase the airflow rate without increasing energy consumption.

Overview of heat-recovery systems

Table 1. Performance overview of four types of heat recovery systems

| Type | Efficiency | Humidity control | Advantages | Disadvantages |

|---|---|---|---|---|

| Rotary wheel | 80+ % | Yes | Compact design | Cross contamination possible, runs on electricity |

| Fixed plate | 50-80% | Yes | No moving parts, no cross contamination | Condesation build-up |

| Heat pipe | 45-55% | No | No moving parts, no corss contamination, compact design | Internal fluid needs to match local climate conditions |

| Run-around | 45-65% | No | Separate airstream, no cross contamination | Multiple pumps require electricity |

How much ventilation do I need to install?

Unfortunately, how many ventilators you need and how big they need to depend on too many factors to give you an indication. For example, the currently present ventilation, the size of the room or building, and the type of ventilation system play a significant role in determining how much additional ventilation you need.

Clean your ventilation equipment

In order to maintain your ventilation equipment and keep them working properly, they need to be cleaned regularly. This is true for highly technical heat recovery equipment as well as for standard ventilation vents.